Knaebel

transducers & gaging

Meet today’s demands for precision measuring and decreasing tolerances with Knaebel’s diverse product line of transducers and gaging products. Improve tool life by using Knaebel systems to measure seat contour, seat form and seat distance to deck face as well as diameters for cylinder heads.

Knaebel Product Line

Knaebel Measuring Devices including adaptable measuring head for differential measurement ; bearing shell measurement with 6 or more measuring points; and connecting rod measurement of all types from small engines to trucks

Knaebel offers complete car body measurement systems for https://horst-knaebel.jimdofree.com/produkte/karosseriemessung/checking the shaft dimensions, gap dimensions and flushness of the body. The evaluation is carried out using portable display devices or stationary measuring computers

videos

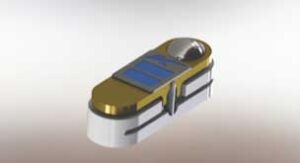

VSM Gage (Valve Seat Measurement). Valve Seat/Guide Geometry Inspection System. VSM measures seat roundness and runout of valve guide to valve seat IN 3 SECONDS! This is repeatable to less than 1 micron. Designed for shop floor use.

The Slidescan Measuring System for Cylinder Heads. The Slidescan is a universal gage and enables the measurement of several seats with a big range of different gage line diameters (ex. between 24mm and 34mm). Cycle time is approx. 4 seconds.