Mytec Hydraclamp & Power Skiving

Skiving has been around for a long time, but recent advances in technology have improved the speed and effectiveness of this gear-making process, making it a more viable manufacturing option for gear producers. It has long been recognized that skiving would be a much more productive process than shaping for cutting many internal gears.

Mytec HYDRACLAMP clamping tools are robust and rigid enough to minimize vibrations caused by the high spindle RPMs and significant cutting forces generated by the new Power Skiving process,” said a spokesperson for Euro- Tech Corporation, the exclusive North American distributor of the Mytec HYDRACLAMP product line.

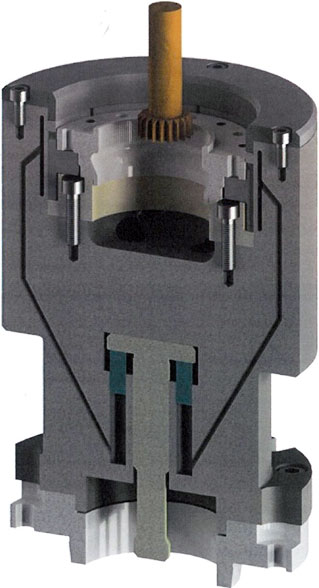

Today’s requirements also include clamping very thin parts for robotic gear boxes (flex spline gear box). Mytec HYDRACLAMP clamping tools are designed to clamp components the entire length of the clamping area. “If the component is irregularly shaped, we clamp around it to achieve the highest accuracy,” said the spokesperson. “View the graphic as an example of a clamping situation with such a component used in the robotic gear box. Note the external shape is irregular and the clamping area is very short. We designed a hydraulic chuck in combination with a changeable back stop and slotted collet. This gives the customer options to clamp different diameters and components with one hydraulic chuck. This hydraulic chuck is used to machine the spline in the gear shaping process on a Liebherr machine.”